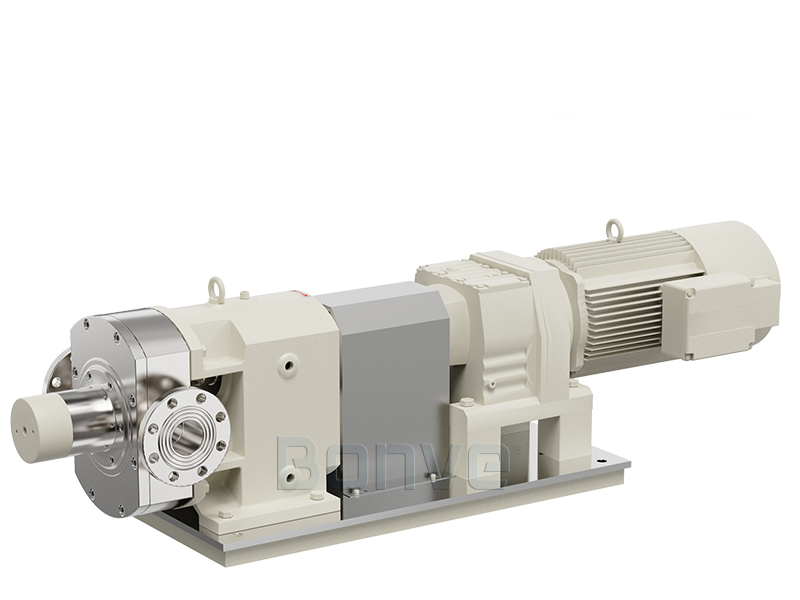

Paper Industry SS2205 Rotary Lobe Pump Calcium Carbonate Slurry Transfer

In paper manufacturing processes requiring calcium carbonate slurry handling, abrasion resistance and leak-free reliability are critical operational priorities.

Bonve's Reinforced Duplex Stainless Steel 2205 Rotary Lobe Pump is precision-engineered to address the rigorous challenges of calcium carbonate slurry transportation.

Unique Structural Advantages

The corrosion-resistant cam rotor design utilizes duplex stainless steel (UNS SS2205/SS1803) for exceptional structural integrity.

Problem-Solving Capabilities

Traditional pumps struggle with calcium carbonate slurry's demanding characteristics:

Abrasive wear from 15-65% solid content

Chemical corrosion in alkaline environments (pH 8-11)

Seal failures causing leakage and downtime

Bonve's engineered solutions deliver unmatched reliability:

Hermetic sealing system: Tandem mechanical seals with silicon carbide faces and EPDM elastomers, rated for 10,000+ hours of continuous operation.

Material superiority: Duplex stainless steel rotors provide 2× higher stress corrosion cracking resistance than standard SS316, with 35% greater yield strength to prevent deformation.

Maintenance optimization: The integrated mechanical seal design can replace all seals within 30 minutes, reducing downtime by 70% compared to conventional split seals.

Industry-Specific Performance Enhancements

Tailored for paper coating and filler preparation systems:

Zero leakage guarantee: Double-sealed shaft protection prevents slurry ingress into bearing assemblies

Particle handling: Accommodates grain sizes up to 0-25mm without clogging

CIP/SIP compatibility: It can support CIP cleaning and replace materials in a short time

Mechanical Seal Innovation

The double face mechanical seal system combines:

Material contact side: SIC material seal in direct contact with calcium carbonate

Secondary seal: Lip-type barrier seal with corrosion-resistant EPDM material and SIC

Integrated flush port: Connection for clean water injection to prolong seal life

Cross-Industry Adaptability

Proven effective in demanding applications:

Filler material preparation: Transfers GCC/PCC slurries with 90% volumetric efficiency

Recycling processes: Handles lime mud suspensions with 25% reduced energy consumption vs centrifugal pumps

This advanced design achieves 95% uptime in paper mills, with 50% lower lifecycle costs compared to traditional slurry pumps.

About Bonve Stainless Steel Lobe Pump

Bonve Lobe Pump is a specialized positive - displacement pump with its non-contact pump element design has the ability to cover a wide range of applications in industry. The hygienic design, anti-corrosive stainless steel construction and smooth pumping action have long established these pumps in the food, beverage, dairy and pharmaceutical industries.

Features include:

• Gentle transfer of delicate suspended solids.

• Bi-directional operation.

• Compact size with high performance and low energy input.

• Ability to pump shear sensitive media.

• Easy maintenance.

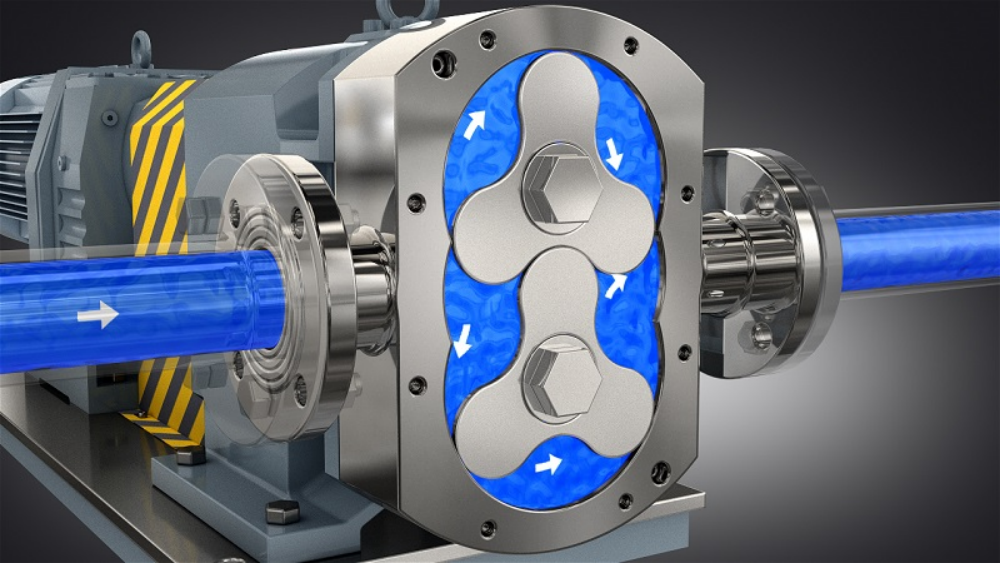

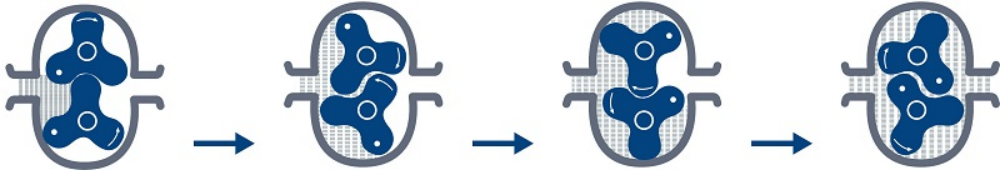

Bonve lobe pumps basically consist of two lobe rotors, which rotate synchronously driven by a pair of synchronous gears in the gearbox. The rotors are driven by the main shaft and sub-shaft to rotate in a synchronous reverse direction, which changes the pump capacity, builds up high vacuum and discharge pressure, thus an efficient pumping is formed. Gap is kept between the rotors and between the pump casing, no friction, long life, no damage, no physical and chemical reaction to the pumped products.

· Bi-wing rotor diagram

·

· Tri-lobe rotors diagram

·

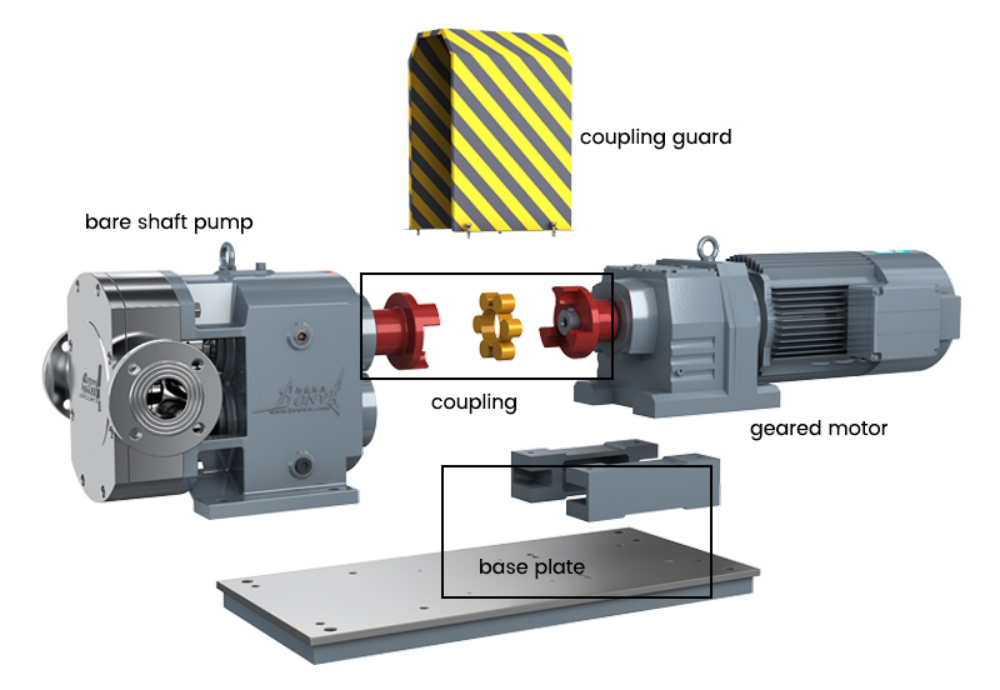

Main Parts of the Complete Pump

Bonve complete pumps are usually composed of bare shaft pump, coupling and its guard, geared motor and base plate. With your order, bare shaft pump or complete pump is supplied.

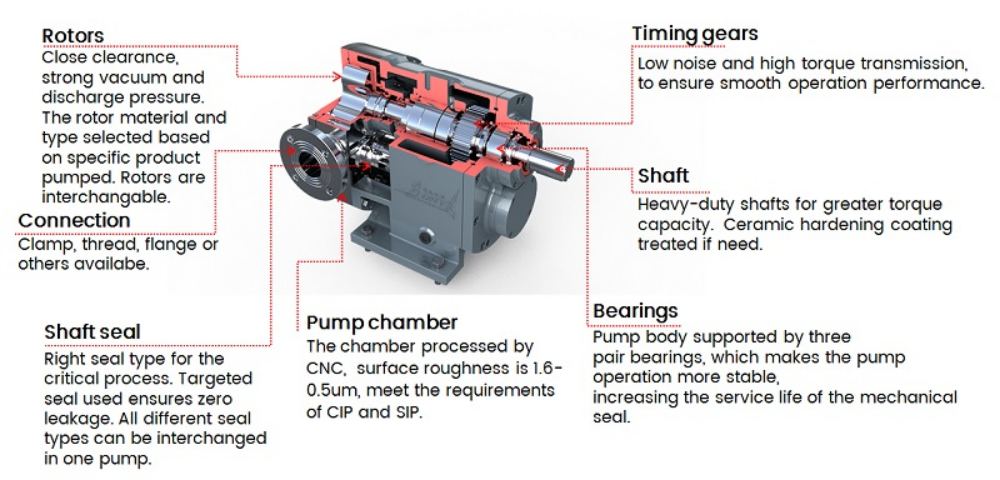

Bare Shaft Pump Structure

Structure Details

Bonve has an advantage over lobe pump that no other company can match.

1.Rotor:The error of the rotors processed by CNC is extremely small. The unique rotor perfectly seals the inlet and outlet of the pump. The vacuum degree of the pump is up to -0.095MPA. The rotor material and type can be selected according to the characteristics of the pumped product.

2.Shaft: The transmission shaft is processed by CNC machining center, which has characteristics of high precision, high bending strength and strong wear resistance.

3.Pump cavity: The pump cavity is sealed by a pump cover that can be opened quickly, enabling quick maintenance of the pump. The pump body is processed by CNC machining.

4.Gears:High-precision, High-Standard synchronous gears have good meshing, smooth transmission, low noise, and excellent bearing capacity.

5.Mechanical seal: The seal material and type are selected according to the characteristic of the pumped product, to ensure zero leakage, no pollution, and more environmental production.

6.Bearings: Six bearings arranged in a separate arrangement increase the concentricity of the pump operation, enhance the bearing capacity of the shaft and make the pump running more stable, thereby increasing the service life of the shaft and the mechanical seal.

7.Gear box: The gear box is processed by CNC, with high precision, high concentricity and strong versatility.

8.Spindle:We use splines the bearings and spindle, makes the pump less likely to slip. The high-precision spline makes the pump run more smoothly, and the service life is much higher than that of its peers.

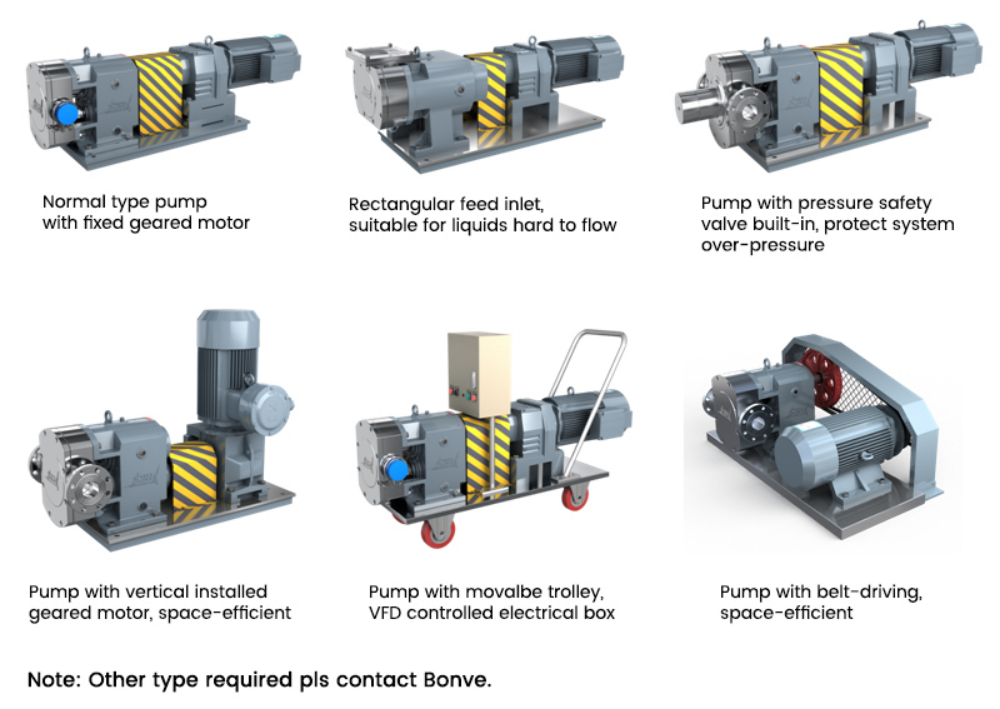

Complete Pump Types

Technical Parameters

|

Model |

Displace -ment |

RPM |

Flow |

Dis. Pre. |

Power |

Vacuum |

Port size |

Max viscosity |

|

|

(L/r) |

(r/min) |

(m³/h) |

(Mpa) |

(kW) |

(Mpa) |

(mm) |

(cp) |

|

25BV12-05 |

0.06 |

10-1000 |

0-0.5 |

0-1.2 |

0.37-1.1 |

-0.080 |

25 |

1,500,000 |

|

40BV12-2 |

0.15 |

10-1000 |

0-2 |

0-1.2 |

0.75-2.2 |

-0.080 |

40 |

1,500,000 |

|

50BV12-5 |

0.32 |

10-800 |

0-5 |

0-1.2 |

1.5-4 |

-0.085 |

50 |

1,500,000 |

|

65BV12-10 |

0.65 |

10-600 |

0-10 |

0-1.2 |

2.2-7.5 |

-0.085 |

65 |

1,500,000 |

|

80BV12-20 |

1.74 |

10-500 |

0-20 |

0-1.2 |

4-15 |

-0.095 |

80 |

1,500,000 |

|

90BV12-30 |

2.60 |

10-500 |

0-30 |

0-1.2 |

5.5-22 |

-0.095 |

100 |

1,500,000 |

|

100BV12-40 |

3.65 |

10-500 |

0-40 |

0-1.2 |

7.5-30 |

-0.095 |

100 |

1,500,000 |

|

125BV12-50 |

4.60 |

10-500 |

0-50 |

0-1.2 |

7.5-37 |

-0.095 |

125 |

1,500,000 |

|

140BV12-70 |

6.10 |

10-500 |

0-70 |

0-1.2 |

11-45 |

-0.095 |

150 |

1,500,000 |

|

150BV12-80 |

7.63 |

10-500 |

0-80 |

0-1.2 |

11-55 |

-0.095 |

150 |

1,500,000 |

|

200BV12-120 |

11.56 |

10-400 |

0-120 |

0-1.2 |

15-75 |

-0.095 |

200 |

1,500,000 |

|

250BV12-150 |

14.22 |

10-400 |

0-150 |

0-1.2 |

18.5-90 |

-0.095 |

250 |

1,500,000 |

|

300BV12-200 |

20.80 |

10-300 |

0-200 |

0-1.2 |

22-110 |

-0.095 |

300 |

1,500,000 |

|

350BV12-300 |

32.60 |

10-250 |

0-300 |

0-1.2 |

45-160 |

-0.095 |

350 |

1,500,000 |

|

400BV12-400 |

50.40 |

10-250 |

0-400 |

0-1.2 |

55-200 |

-0.095 |

400 |

1,500,000 |

Note:

1. Tested medium: water. Your liquid's density, viscosity and temperature are necessary to supply when choose the pump.

2. Speed, flow rate, electrical power and pressure will be varified according to different liquid properties.

3. Port size can be changed as needed.

Selection Guidelines

|

Your Industry |

|

||

|

About pump medium |

Name: |

||

|

Density (g/m³): |

|||

|

Viscosity (mPa.s): |

|||

|

Temperature (℃): |

|||

|

PH value: |

|||

|

Solid content (%): |

|||

|

Solid size (mm): |

|||

|

Suction side |

Pressure: Positive ( ) bar; Negtive ( ) bar |

How high (m): |

|

|

Suction pipe length (m): |

Diameter (mm): |

||

|

Bends (Pcs): |

T-piece (Pcs): |

Valves (Pcs): |

|

|

Discharge side |

Pressure (Mpa): |

||

|

Vertical delivery pipe length (m): Total delivery pipe length (m): |

Diameter (mm): |

||

|

Bends (Pcs): |

T-piece (Pcs): |

Valves (Pcs): |

|

|

Required flow rate (L/H) |

Operating flow: |

Max. flow: |

|

|

Pump material required |

SS304 ( ) SS316 ( ) SS316L ( ) Duplex stainless steel ( ) |

||

|

Motor required |

Phase: Single ( ) Three ( ) |

Voltage (V): |

Frequency (Hz): |

|

IP grade: |

Energy efficiency: |

Anti-explosive: |

|

|

Installation type |

Fixed ( ) |

Movable ( ) |

% |

Contact Us

Don't miss out on the opportunity to upgrade your calcium carbonate transfer process—contact us today to learn more or request a quote!

Contact person: Luke Pan

Tel: +86-574-87769810 Fax: +86-574-62962898

Mobile/Whatsapp/Wechat: +86 13586591843

Email: bvsales3@bonvepumps.com