Bonve SS316L Rotary Lobe Pump for High-Viscosity Acrylic Resin Coatings Handling

In industrial coating operations requiring precision handling of viscous polymer systems, shear stability, corrosion resistance, and material homogeneity preservation are critical priorities.

Bonve's 316L Stainless Steel Rotary Lobe Pump is engineered to address the unique challenges of transporting high-viscosity acrylic resin coatings (8,000-50,000 cP) while maintaining critical rheological properties.

Enhanced Structural Advantages

The corrosion-resistant Bi-wing rotor system features hardened 316L stainless steel with surface roughness <0.8μm Ra, preventing resin buildup.

Enhanced clearance control (0.1-0.3mm adjustable) ensures optimal handling of thixotropic materials.

Problem-Solving Capabilities

Traditional pumps fail with acrylic resin's demanding characteristics:

- Shear-induced viscosity breakdown and molecular chain damage

- Pigment/particle separation in filled systems (≤15% solids content)

- Material curing in flow channels

- Solvent resistance challenges

Bonve's Engineered Solutions

1.Shear-Critical Operation

Bi-wing rotors with 0-40 RPM ultra-low speed range maintain viscosity integrity

Tapered feed channels prevent air entrapment in pseudoplastic fluids

2.Chemical-Resistant Sealing

Dual cartridge seals with:

- Primary face: Silicon carbide/Tungsten carbide (SiC/TC)

- Secondary seal: FFKM perfluoroelastomer (ASTM D2000 compliant)

- Full solvent resistance (compatible with acetone, xylene, MEK)

3.Process-Optimized Design

- Thermal control jacket maintains 35-60°C (±1°C) for viscosity management

- Flush port configuration prevents curing during standby (compatible with <5μm filtration)

Industry-Specific Enhancements

1.Particle Handling

Maintains dispersion stability for filled systems:

- Handles particle loads ≤15% (zinc phosphate, TiO₂ ≤100μm)

- <0.5% viscosity variation during transfer

2.Cleaning Efficiency

- Full solvent CIP capability with 360° flush coverage

- Disassembly in ≤5 minutes for rotor or seal changeovers

Mechanical Seal Innovation

Patented Quad-Ring™ sealing system features:

- Split-seal replacement in ≤5 minutes (90% faster than standard)

- Springless PTFE wedge design prevents particulate trapping

- 10,000-hour MTBF with abrasive media

Performance Data

- Maintains 99.2% viscosity retention at 8,000-50,000cps

- 0.02% batch-to-batch contamination rate

- 40% lower energy consumption vs. gear pumps in high viscosity system

- Achieves 98.5% uptime in 24/7 automotive coating lines

This engineering solution enables reliable transfer of solvent-borne and UV-cure acrylic resins while preserving critical application properties - including sag resistance, leveling characteristics, and pot life stability.

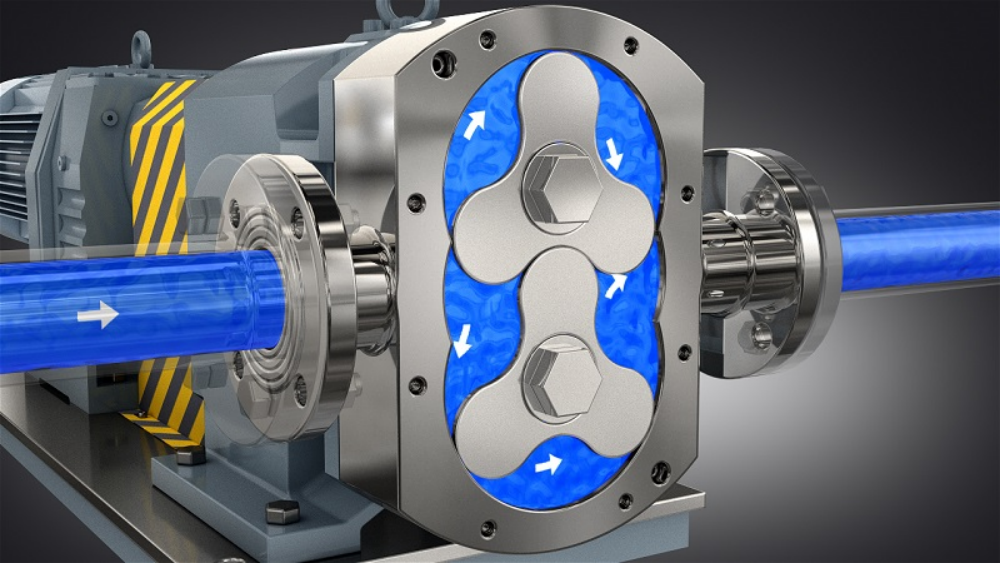

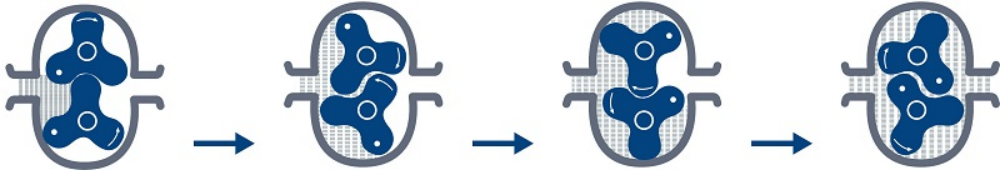

Bonve lobe pumps basically consist of two lobe rotors, which rotate synchronously driven by a pair of synchronous gears in the gearbox. The rotors are driven by the main shaft and sub-shaft to rotate in a synchronous reverse direction, which changes the pump capacity, builds up high vacuum and discharge pressure, thus an efficient pumping is formed. Gap is kept between the rotors and between the pump casing, no friction, long life, no damage, no physical and chemical reaction to the pumped products.

· Bi-wing rotor diagram

·

· Tri-lobe rotors diagram

·

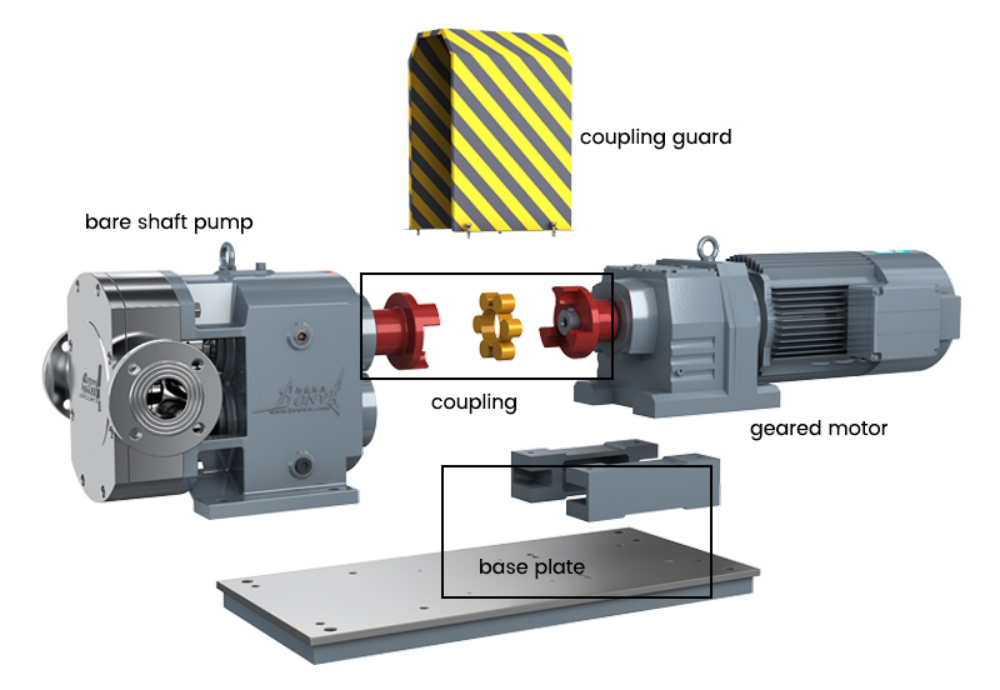

Main Parts of the Complete Pump

Bonve complete pumps are usually composed of bare shaft pump, coupling and its guard, geared motor and base plate. With your order, bare shaft pump or complete pump is supplied.

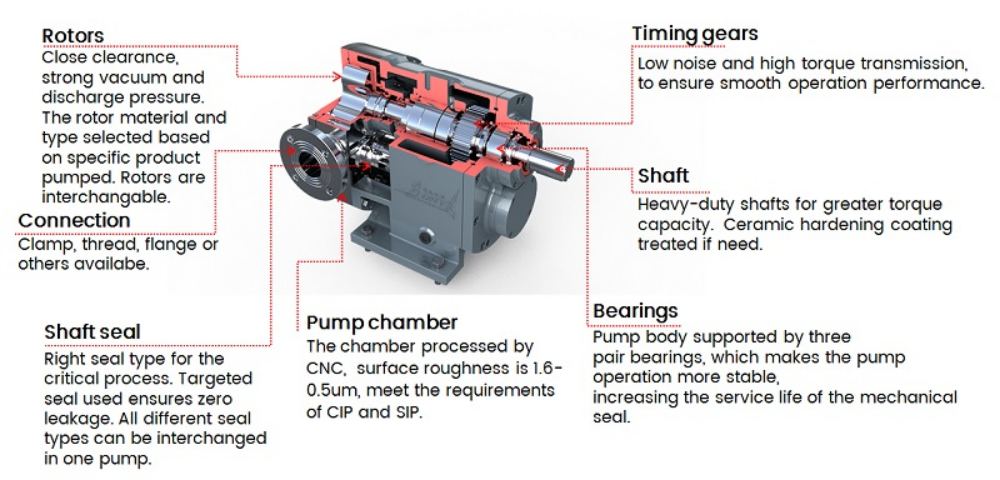

Bare Shaft Pump Structure

Structure Details

Bonve has an advantage over lobe pump that no other company can match.

1.Rotor:The error of the rotors processed by CNC is extremely small. The unique rotor perfectly seals the inlet and outlet of the pump. The vacuum degree of the pump is up to -0.095MPA. The rotor material and type can be selected according to the characteristics of the pumped product.

2.Shaft: The transmission shaft is processed by CNC machining center, which has characteristics of high precision, high bending strength and strong wear resistance.

3.Pump cavity: The pump cavity is sealed by a pump cover that can be opened quickly, enabling quick maintenance of the pump. The pump body is processed by CNC machining.

4.Gears:High-precision, High-Standard synchronous gears have good meshing, smooth transmission, low noise, and excellent bearing capacity.

5.Mechanical seal: The seal material and type are selected according to the characteristic of the pumped product, to ensure zero leakage, no pollution, and more environmental production.

6.Bearings: Six bearings arranged in a separate arrangement increase the concentricity of the pump operation, enhance the bearing capacity of the shaft and make the pump running more stable, thereby increasing the service life of the shaft and the mechanical seal.

7.Gear box: The gear box is processed by CNC, with high precision, high concentricity and strong versatility.

8.Spindle:We use splines the bearings and spindle, makes the pump less likely to slip. The high-precision spline makes the pump run more smoothly, and the service life is much higher than that of its peers.

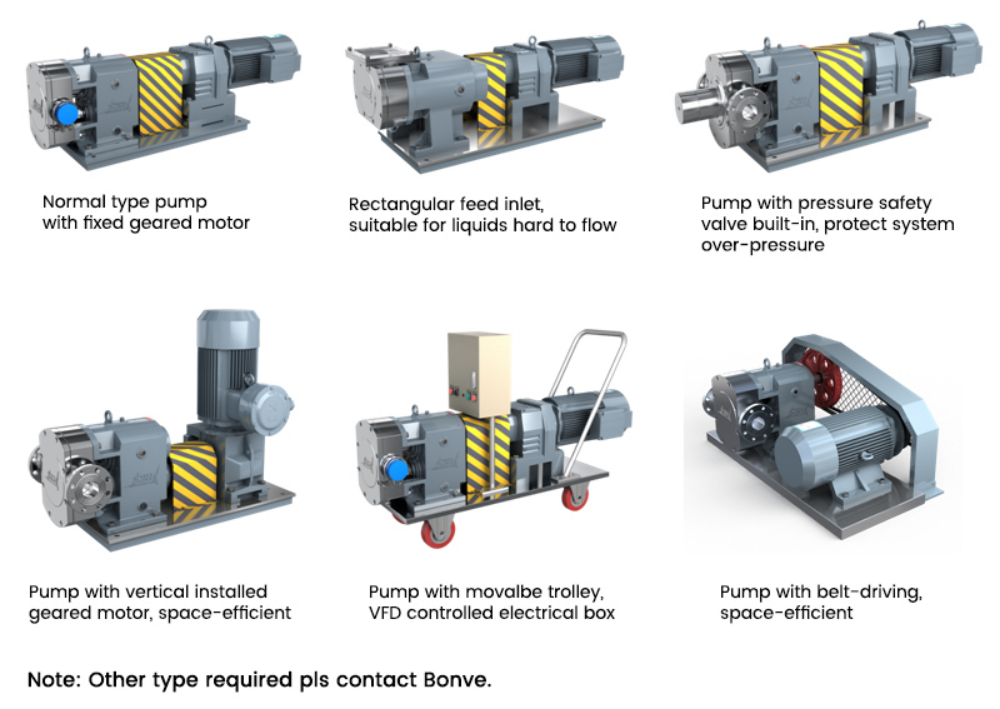

Complete Pump Types

Technical Parameters

|

Model |

Displace -ment |

RPM |

Flow |

Dis. Pre. |

Power |

Vacuum |

Port size |

Max viscosity |

|

|

(L/r) |

(r/min) |

(m³/h) |

(Mpa) |

(kW) |

(Mpa) |

(mm) |

(cp) |

|

25BV12-05 |

0.06 |

10-1000 |

0-0.5 |

0-1.2 |

0.37-1.1 |

-0.080 |

25 |

1,500,000 |

|

40BV12-2 |

0.15 |

10-1000 |

0-2 |

0-1.2 |

0.75-2.2 |

-0.080 |

40 |

1,500,000 |

|

50BV12-5 |

0.32 |

10-800 |

0-5 |

0-1.2 |

1.5-4 |

-0.085 |

50 |

1,500,000 |

|

65BV12-10 |

0.65 |

10-600 |

0-10 |

0-1.2 |

2.2-7.5 |

-0.085 |

65 |

1,500,000 |

|

80BV12-20 |

1.74 |

10-500 |

0-20 |

0-1.2 |

4-15 |

-0.095 |

80 |

1,500,000 |

|

90BV12-30 |

2.60 |

10-500 |

0-30 |

0-1.2 |

5.5-22 |

-0.095 |

100 |

1,500,000 |

|

100BV12-40 |

3.65 |

10-500 |

0-40 |

0-1.2 |

7.5-30 |

-0.095 |

100 |

1,500,000 |

|

125BV12-50 |

4.60 |

10-500 |

0-50 |

0-1.2 |

7.5-37 |

-0.095 |

125 |

1,500,000 |

|

140BV12-70 |

6.10 |

10-500 |

0-70 |

0-1.2 |

11-45 |

-0.095 |

150 |

1,500,000 |

|

150BV12-80 |

7.63 |

10-500 |

0-80 |

0-1.2 |

11-55 |

-0.095 |

150 |

1,500,000 |

|

200BV12-120 |

11.56 |

10-400 |

0-120 |

0-1.2 |

15-75 |

-0.095 |

200 |

1,500,000 |

|

250BV12-150 |

14.22 |

10-400 |

0-150 |

0-1.2 |

18.5-90 |

-0.095 |

250 |

1,500,000 |

|

300BV12-200 |

20.80 |

10-300 |

0-200 |

0-1.2 |

22-110 |

-0.095 |

300 |

1,500,000 |

|

350BV12-300 |

32.60 |

10-250 |

0-300 |

0-1.2 |

45-160 |

-0.095 |

350 |

1,500,000 |

|

400BV12-400 |

50.40 |

10-250 |

0-400 |

0-1.2 |

55-200 |

-0.095 |

400 |

1,500,000 |

Note:

1. Tested medium: water. Your liquid's density, viscosity and temperature are necessary to supply when choose the pump.

2. Speed, flow rate, electrical power and pressure will be varified according to different liquid properties.

3. Port size can be changed as needed.

Selection Guidelines

|

Your Industry |

|

||

|

About pump medium |

Name: |

||

|

Density (g/m³): |

|||

|

Viscosity (mPa.s): |

|||

|

Temperature (℃): |

|||

|

PH value: |

|||

|

Solid content (%): |

|||

|

Solid size (mm): |

|||

|

Suction side |

Pressure: Positive ( ) bar; Negtive ( ) bar |

How high (m): |

|

|

Suction pipe length (m): |

Diameter (mm): |

||

|

Bends (Pcs): |

T-piece (Pcs): |

Valves (Pcs): |

|

|

Discharge side |

Pressure (Mpa): |

||

|

Vertical delivery pipe length (m): Total delivery pipe length (m): |

Diameter (mm): |

||

|

Bends (Pcs): |

T-piece (Pcs): |

Valves (Pcs): |

|

|

Required flow rate (L/H) |

Operating flow: |

Max. flow: |

|

|

Pump material required |

SS304 ( ) SS316 ( ) SS316L ( ) Duplex stainless steel ( ) |

||

|

Motor required |

Phase: Single ( ) Three ( ) |

Voltage (V): |

Frequency (Hz): |

|

IP grade: |

Energy efficiency: |

Anti-explosive: |

|

|

Installation type |

Fixed ( ) |

Movable ( ) |

% |

Contact Us

Don't miss out on the opportunity to upgrade your calcium carbonate transfer process—contact us today to learn more or request a quote!

Contact person: Luke Pan

Tel: +86-574-87769810 Fax: +86-574-62962898

Mobile/Whatsapp/Wechat: +86 13586591843

Email: bvsales3@bonvepumps.com