Sanitary Grade Lobe Pump for Sesame Sauce Peanut Butter Mustard

Sesame Sauce Peanut Butter Mustard transfer pump

Sesame sauce peanut butter mustard is a premium condiment that people love to add to their food. In the process of making Sesame sauce peanut butter mustard, it will be very thick after homogenization and emulsification. How to transfer sesame sauce peanut butter mustard to storage tanks or filling machines is a problem that needs to be solved. Sanitary lobe pump as a high viscosity liquid transfer pump, very suitable. The lobe pump for sesame sauce peanut butter mustard sauce application cases are very many, and liquid contact parts are all stainless steel to ensure that they can meet sanitary grade standards. Bonve is the leading lobe pump manufacturers in China who can offer an efficient pump to transfer.

What Pump We Offer?

Bonve offers the broadest range of its Rotary Lobe Pumps for food industry. As an excellent pump manufacturer, our hard technical barriers have become a powerful help for our Bonve pumps reform and innovation. So far, Bonve pumps have developed to the fourth generation and are mature.

Interchangeable

- Interchangeable rotors, one pump multi-purpose.

- Targeted seal for specific application, ensure zero leakage.

Easy maintenance

- Compact structure, easy assembling and disassembling

- Maintenance in place, easy cleaning, CIPable and SIPable.

- Few wearing parts, low maintenance.

Long life

- All main parts proceed by CNC, high precision fabrication.

- No contact between the rotors, rotors and pump chamber.

- Six bearings with separate arrangement, high balance.

- Adjustable seal ring extends the shaft life.

- Axis key synchronous adjustment, no rotor collision problem.

Working Principle

Bonve lobe pumps basically consist of two lobe rotors, which rotate synchronously driven by a pair of synchronous gears in the gearbox. The rotors are driven by the main shaft and sub-shaft to rotate in a synchronous reverse direction, which changes the pump capacity, builds up high vacuum and discharge pressure, thus an efficient pumping is formed. Gap is kept between the rotors and between the pump casing, no friction, long life, no damage, no physical and chemical reaction to the pumped products.

Bi-wing rotor diagram

Tri-lobe rotors diagram

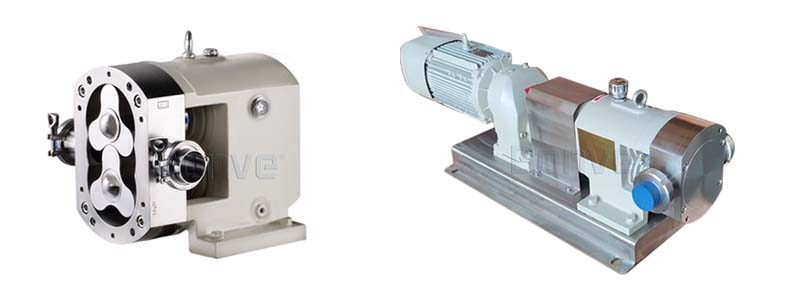

Main Parts of the Complete Pump

Bonve complete pumps are usually composed of bare shaft pump, coupling and its guard, geared motor and baseplae. With your order, bare shaft pump or complete pump is supplied.

Bare Shaft Pump Structure

Based on the port direction, we have the pump with horizontal port and vertical port to meet your site installation.

Structure Details

Complete Pump Types

Technical Parameters

|

Model |

Displace -ment |

RPM |

Flow |

Dis. Pre. |

Power |

Vacuum |

Port size |

Max viscosity |

|

(L/r) |

(r/min) |

(m³/h) |

(Mpa) |

(kW) |

(Mpa) |

(mm) |

(cp) |

|

|

25BV12-05 |

0.06 |

10-1000 |

0-0.5 |

0-1.2 |

0.37-1.1 |

-0.080 |

25 |

1,500,000 |

|

40BV12-2 |

0.15 |

10-1000 |

0-2 |

0-1.2 |

0.75-2.2 |

-0.080 |

40 |

1,500,000 |

|

50BV12-5 |

0.32 |

10-800 |

0-5 |

0-1.2 |

1.5-4 |

-0.085 |

50 |

1,500,000 |

|

65BV12-10 |

0.65 |

10-600 |

0-10 |

0-1.2 |

2.2-7.5 |

-0.085 |

65 |

1,500,000 |

|

80BV12-20 |

1.74 |

10-500 |

0-20 |

0-1.2 |

4-15 |

-0.095 |

80 |

1,500,000 |

|

90BV12-30 |

2.60 |

10-500 |

0-30 |

0-1.2 |

5.5-22 |

-0.095 |

100 |

1,500,000 |

|

100BV12-40 |

3.65 |

10-500 |

0-40 |

0-1.2 |

7.5-30 |

-0.095 |

100 |

1,500,000 |

|

125BV12-50 |

4.60 |

10-500 |

0-50 |

0-1.2 |

7.5-37 |

-0.095 |

125 |

1,500,000 |

|

140BV12-70 |

6.10 |

10-500 |

0-70 |

0-1.2 |

11-45 |

-0.095 |

150 |

1,500,000 |

|

150BV12-80 |

7.63 |

10-500 |

0-80 |

0-1.2 |

11-55 |

-0.095 |

150 |

1,500,000 |

|

200BV12-120 |

11.56 |

10-400 |

0-120 |

0-1.2 |

15-75 |

-0.095 |

200 |

1,500,000 |

|

250BV12-150 |

14.22 |

10-400 |

0-150 |

0-1.2 |

18.5-90 |

-0.095 |

250 |

1,500,000 |

|

300BV12-200 |

20.80 |

10-300 |

0-200 |

0-1.2 |

22-110 |

-0.095 |

300 |

1,500,000 |

|

350BV12-300 |

32.60 |

10-250 |

0-300 |

0-1.2 |

45-160 |

-0.095 |

350 |

1,500,000 |

|

400BV12-400 |

50.40 |

10-250 |

0-400 |

0-1.2 |

55-200 |

-0.095 |

400 |

1,500,000 |

Note:

1. Tested medium: water. Your liquid's density, viscosity

and temperature are necessary to supply when choose the pump.

2. Speed, flow rate, electrical power and pressure will be

varified according to different liquid properties.

3. Port size can be changed as needed.

Selection Guidelines

|

Your Industry |

|||

|

About pump medium |

Name: |

||

|

Density (g/m³): |

|||

|

Viscosity (mPa.s): |

|||

|

Temperature (℃): |

|||

|

PH value: |

|||

|

Solid content (%): |

|||

|

Solid size (mm): |

|||

|

Suction side |

Pressure: Positive ( ) bar; Negtive ( ) bar |

How high (m): |

|

|

Suction pipe length (m): |

Diameter (mm): |

||

|

Bends (Pcs): |

T-piece (Pcs): |

Valves (Pcs): |

|

|

Discharge side |

Pressure (Mpa): |

||

|

Vertical delivery pipe length (m): Total delivery pipe length (m): |

Diameter (mm): |

||

|

Bends (Pcs): |

T-piece (Pcs): |

Valves (Pcs): |

|

|

Required flow rate (L/H) |

Operating flow: |

Max. flow: |

|

|

Pump material required |

SS304 ( ) SS316 ( ) SS316L ( ) Duplex stainless steel ( ) |

||

|

Motor required |

Phase: Single ( ) Three ( ) |

Voltage (V): |

Frequency (Hz): |

|

IP grade: |

Energy efficiency: |

Anti-explosive: |

|

|

Installation type |

Fixed ( ) |

Movable ( ) |

Fixed with adjusting feet ( ) |

|

Others |

|||

About Us

BONVE is a Chinese leading manufacturer in ROTARY LOBE PUMPS and HOMOGENIZER MIXERS. Providing its customers with customized pumping and mixing solutions and solving their problems during the production.

Bonve pumps and mixers are widely used in food, dairy, beverages, chemical, pulp&paper, soaps&detergents, pharmaceuticals, pesticide, coatings etc. By 2020, Bonve served 4,000+ customers in various industries and 50,000+ pumps running in the worldwide.

Time and again companies specify Bonve pumps as the "standard" equipment for their manufacturing processed. We are looking forward to be partner with you.

Contact Us

We welcome you to contact us for a pump solution if have any demand.

Contact person: Mr. Andre

Tel: +86-574-87769810 Fax: +86-574-62962898

Mobile/Whatsapp/Wechat: +86 15888591452

Email: bvsales2@bonvepumps.com